The Different Types of Woodworking Bench Dogs

While the 20 x 96 mm hole standard popularized by workstations like the Festool MFT/3® Multifunction Table seems to be all the rage today, hole-patterned woodworking worktops are hardly a novel concept. In fact, bench holes, holdfasts, and dogs have been around for thousands of years and are still commonly used. They act as removable clamps to temporarily fix a workpiece in place for planing, sawing, or other woodworking tasks. Today, the rising acceptance of the 20 x 96 mm hole standard means woodworkers have a broad selection of 20 mm accessories to choose from. In this article, we’ll explore the different types of woodworking bench dogs.

Anatomy of a Bench Dog

While bench dogs have several physical differences based on their specific uses, we can define some standard terminology to help you understand how bench dogs work.

- The shaft represents the uppermost section of the bench dog and sits proud of your work surface.

- The collar is larger than the body diameter and prevents the dog from falling through the bench top. Certain styles of bench dogs, like those with a chamfer, don’t have a large protruding collar but rather a small lip that recesses into the chamfer in your workbench.

- The body is the portion of the dog that fits inside your workbench hole. Often, the body (or the entire length of the dog) will feature a tapped hole with metric thread. This allows it to accept clamping knobs inserted from underneath the table to rigidly secure the bench dog to your work surface.

Getting the Right Fit

While it may seem like an easy task, getting the “just-right” fit for a 20 mm bench dog can prove a challenge. Bench dogs made for 20 mm holes are usually slightly undersized. Worktops made to the 20 x 96 mm hole standard can frequently have a high degree of variation from hole to hole. This could be from poor manufacturing tolerances, swelling and variations in the work surface due to changing humidity levels, or wear on the hole over time.

Some 20 mm bench dogs may fit too tight (or not at all), and others may fit with too much lateral slop. For this reason, some bench dog manufacturers like TSO offer woodworking bench dogs with different fits (standard fit and “close fit”). We also offer a selection of accessories to revitalize 20 mm holes in your worktop to the perfect fit.

Bench Dog Role 1: Standard Work Holding

Looking for bench dogs to fill the traditional role of work-holding and fixturing duties? A standard collared dog, such as our 20 mm DoubleGroove™ Dogs, would work well for this application. These dogs feature a large, 25 mm diameter collar, making them easy to remove. They’re available in different body protrusion lengths to handle worktops of different thicknesses: small (18 mm protrusion into your worktop), large (30 mm protrusion), and tall (70 mm protrusion above, 18mm below).

Bench Dog Role 2: Repeatable Positioning

When positioning accuracy is paramount, it is essential to minimize “slop” caused by poor-fitting bench dogs. “Close Fit” Bench Dogs are one type of woodworking bench dog. Rather than a body diameter of 19.90 mm, Close Fit Dogs feature a 19.98 mm diameter precision-machined body that fits into a 20 mm bench dog hole with essentially zero lateral play. While Close Fit Dogs provide an answer for optimal positioning accuracy, for day-to-day use, they might be less than ideal. Manufacturing variances present in high-volume workbenches can result in a frustratingly tight fit. To address this, TSO sells a variety of hole prep tools, including a Reamer Tool or Combined Chamfer & Reamer Tool that can refurbish your 20 mm holes to a perfect fit.

Chamfer Dogs are another viable answer when positioning accuracy is of the utmost importance. Rather than relying on the fit between the inner walls of the workbench hole and the outer body diameter of the bench dog, Chamfer Dogs rest on their chamfered lip. This ensures the dog is always self-centering inside the hole.

To get the full benefit of Chamfer Dogs, you must use them in chamfered 20 mm dog holes. For hardwood veneered plywood, a quality 45° chamfer router bit will make quick work of chamfering your dog holes. Chamfering your work surface’s holes provides another benefit: by removing the hard edges, you reduce the likelihood of catching a finger on a hard edge.

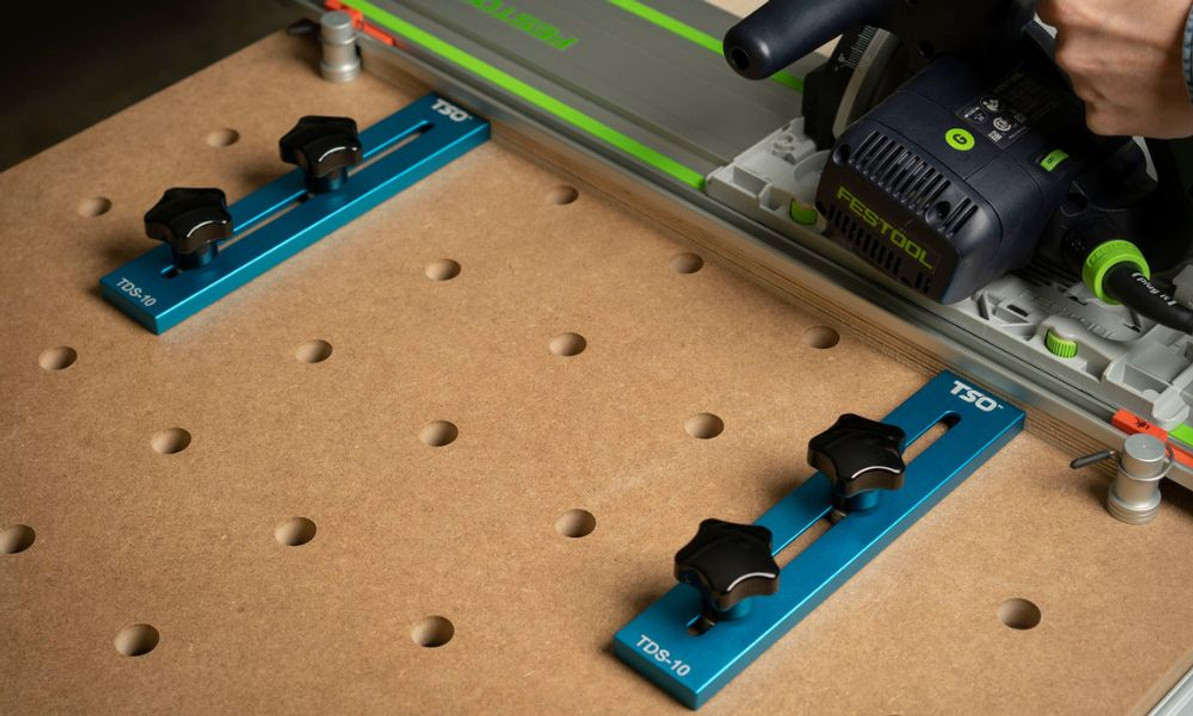

Bench Dog Role 3: Guide Rail Holding

Specialized bench dogs connect a track saw guide rail to a 20 mm worktop. This is critical for those building their own DIY 20 x 96 mm hole-patterned workbench and not relying on the guide rail support and hinge system found on mass-produced products. Guide Rail Dogs work by attaching themselves to the underside of your guide rail via a T-slot.

Once attached to the bottom of your guide rail, the assembly inserts into your 20 mm worktop, and the workpiece then slides underneath to its cutting position. This ensures you’re always cutting workpieces at the same position on your table and receiving the full “zero-clearance” benefit that the table provides to prevent tearout and give you better quality cuts.

Another affordable option for connecting your guide rail to a 20 mm top combines Dog Rail Clips and specific bench dogs. These bench dogs provide a tall enough shaft to accommodate the thickness of workpieces you’re likely to encounter. Typically, TSO customers will pair Tall Dogs with Dog Rail Clips to form a complete solution. While this attachment method doesn’t offer the same flexibility as Guide Rail Dogs in handling a wide range of material thicknesses and keeping the guide rail elevated between cuts, many prefer this approach for its speed and simplicity.

Bench Dog Role 4: Modular/Expanding Worktops

Portability and expandability are traits that are highly valued on jobsites. TSO has introduced two “bench-connecting” dogs specifically for this purpose: Power-Loc Dogs and Smart Connect Dogs. Both dogs feature a chamfered lip that sits flush or slightly underneath your work surface. When it comes to expanding or connecting work surfaces, these dogs provide strong clamping action and precise registration, and they won’t interfere with your work.

Bench Dog Role 5: Standalone Clamping

Bench dogs can be more than just a material stop; in fact, they can be a strong foundation for an entire clamping system. For example, our Power-Loc Toggle Clamp integrates a special version of our Power-Loc Bench Dog to secure entirely from the top of your workbench. It accomplishes this thanks to an innovative swiveling locking lug feature. This eliminates the need to use a clamping knob or another fastening method from underneath your table. Simply insert this heavy-duty toggle clamp into any 20 mm hole. While it’s in its upright position, use a 5 mm hex driver or key to securely fix it to your table. It’s quick, convenient, and strong.

Bench Dog Role 6: Standoffs

Also called “workbench protection dogs,” these bench dogs serve a single purpose: to keep your workpiece elevated and off the table. This can be useful come glue up, when you need to get clamps underneath a casing. It’s also great for finishing, when you want to avoid getting a finish over your bench and aid cleanup later. TSO provides workbench protection dogs, work support dogs, and paint points for this purpose. Typically, these dogs feature a nonslip material on the top, and many will also include a height-adjustment feature to fine-tune the standoff distance.

Recent Posts

-

Can You Use a Track Saw To Joint Boards?

Jointing boards is a crucial step in woodworking and generally involves flattening one face and one …3rd Jul 2024 -

Can a Circular Saw Be Converted Into a Track Saw?

Track and circular saws serve distinct purposes in the world of woodworking and construction. While …6th Jun 2024 -

Achieving Perfectly Straight Dados and Rabbets With a Router

Achieving dead-straight dados and rabbets isn’t something you can free-hand. With the right tools an …5th Jun 2024