Description

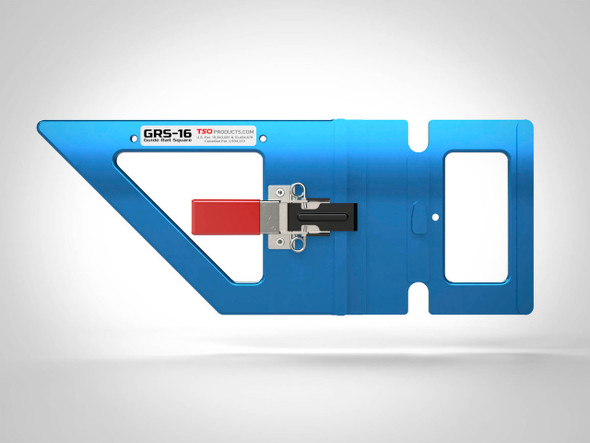

When it comes to repeatable accuracy, a well-designed T-track FlipStop might just be the most important single component in your jig, fixture or fence—which is why we have obsessed over perfecting it. The result is our TPG FlipStop v2.0, embodying the quality and capability of the entire TPG System with an attention to detail you won't find in any other material stop on the market.

While our TPG Sets include a FlipStop for every T-track, additional FlipStops can be added and permanently left installed—especially convenient if you find yourself making the same two or three rips frequently.

- Exclusive Calibration Memory™ collar eliminates the need to re-calibrate the FlipStop when switching between Standard and Narrow Stock Rods

- The fastest-to-calibrate on the market: watch this video to see how easy it is

- Parallax free cursor makes it easy to read T-track dimension and dial in your exact setting

- Comfort Grip Star Knobs for quick lock and release, even with gloves on

- Internal spring loading against TPG T-track means that even when the FlipStop knob is loosened, you won't accidently move it along the T-track as you turn the Star Knob to lock in a setting—a common problem with lesser material stops

A Closer Look at TPG FlipStop v2.0: Another TSO Gamechanger

Material stops are often an afterthought—but why? They’re the part of the system you interact with the most, and critical at setting and maintaining accurate cuts. See what sets the TPG FlipStop v2.0 apart in the video below:

What's Included in the Box

- 1 qty. TPG FlipStop v2.0

- 1 qty. Standard Calibration Rod

- 1 qty. Calibration Memory Collar

Tips for Using the TPG FlipStop

Watch the video below for some helpful tips on using (and particularly, sighting and setting) the TPG FlipStop for extremely accurate cuts.

Videos

-

TSO Products parallel guide festool makita triton track saw Dave Stanton woodwork joinery

TSO Products Parallel Guide System Unboxing and walk through. ...

-

TPG FlipStop v2.0 for the TSO Parallel Guide System

When it comes to repeatable accuracy, a well-designed FlipStop...

-

Using the TPG FlipStp v2.0 for TSO Parallel Guide System

When it comes to repeatable accuracy, a well-designed FlipStop...

Warranty & Returns

12 Reviews

-

Excellent Design and Fit and Finish

The design is probably the best flipstop design out there that I have seen. It is simple and effective with an excellent fit and finish.

-

Flip stop works great

The TSO flip stop is a great product! I love the overall fit and finish as well as the calibration collar. Cslibraid very easy

-

Disappointed

At first glance, the calibration "memory" seemed like a great thing, so I sprung for a set. Then I discovered that my something (maybe the tracks) in my system is off and the calibration from stop to stop is not consistent. On my setup there is about 1 mm of variation. This means that you have to keep track of which which rod goes with which stop -- if you get it wrong the error is going to be twice the difference between the calibration settings. I'm still thinking on how to track which rod goes with which stop. I suppose it wouldn't be a problem if you're using a single track with a rail square.

-

Flip stop v2.0

Excellent product . Very accurate and consistent best in the business

-

Excellent Quality

I love the TSO Parallel Guides! My only complaint is these recent TSO products are a deep dark Blue than my originals like the picture but these tools were meant for work not a beauty pageant! LOL