Top Miter Saw Stands: From Budget to Professional Grade

A miter saw without proper support turns precision cutting into guesswork. After years of dealing with inadequate stands that sag under load, bind during setup, or lack key features, the difference between a purpose-built stand and a compromise choice becomes obvious the first time you need to make repetitive cuts or move between locations.

The challenge isn't finding any stand, it's matching the right support system to your saw, workspace, and actual working conditions.

Types of Miter Saw Stands

Traditional Fixed Stands provide maximum stability for dedicated shop setups. They excel when cutting large crown molding or making precision cuts, but mobility is obviously limited.

Folding Stands with Wheels address the fundamental portability problem of heavy miter saws. Quality matters here. Cheap stands with small solid wheels become useless on gravel or uneven surfaces, while pneumatic wheels handle rough terrain but add weight and complexity.

Rail/Beam Style Stands solve the long workpiece problem by extending support outward. Setup takes longer, but they eliminate the need for separate support stands when cutting trim or lengthy stock.

Tabletop Stands work for lighter saws and occasional use but lack the stability needed for larger sliding compound models.

Key Selection Factors

Portability vs. Stability: A Bosch 12" sliding saw weighs over 60 pounds. Add a substantial stand and you're moving 100+ pounds. If genuine portability matters, accept that lighter stands mean stability compromises.

Workpiece Support: Long trim and crown molding demand extended support. Without proper outfeed support, even basic cuts become challenging as material sags during cutting.

Storage Reality: Folding stands rarely fold as compactly as expected, especially with the saw mounted. Factor actual storage space, not marketing claims.

Saw Compatibility: Mounting hole patterns vary between brands. Universal stands work through adjustable systems, but brand-specific stands typically offer tighter integration.

Top Stand Recommendations

Bosch T4B Gravity Rise - Best for Heavy Saws

The T4B earns its reputation through consistent performance under demanding conditions. The gravity-assist folding mechanism lives up to the hype—setup genuinely takes seconds once you understand the sequence. More importantly, the stand handles heavy sliding compound saws without the flex or wobble that plagues lighter alternatives.

The pneumatic wheels make the difference on job sites with gravel or uneven terrain. Where solid wheels bind or refuse to roll, the T4B keeps moving. The trade-off is weight. This isn't a stand you'll enjoy carrying upstairs, but for ground-level work or shop use where the saw stays mounted, the stability justifies the bulk.

Mounting compatibility covers most major brands, though Bosch saws integrate most naturally. The quick-release levers work smoothly after break-in, but expect to pay premium pricing for this level of engineering.

Best for: Heavy sliding saws (12" and larger), job site work on varied terrain, users who prioritize setup speed and stability over portability.

DeWalt DWX726 - Solid Integration for DeWalt Users

DeWalt designed this stand specifically around their saw lineup, and the integration shows. The mounting system aligns perfectly with DeWalt saws, and the quick-release mechanism speeds daily setup significantly compared to universal stands requiring adjustment.

The folding action feels adequate rather than exceptional—it gets the job done without the refined smoothness of premium options. The wheels handle hard surfaces well but struggle more than pneumatic alternatives on loose gravel or rough terrain. For shop use or job sites with decent access, this limitation rarely matters.

The stand supports most DeWalt sliding compound saws effectively, though it feels less robust than the Bosch when loaded with larger 12" models. The price point reflects this positioning—solid performance without premium features or pricing.

Best for: DeWalt saw owners, shop use with occasional portability needs, budget-conscious users wanting brand integration.

BORA PM-4000 - Extended Support Specialist

When long workpieces dominate your cutting, the PM-4000's rail system eliminates the constant struggle with auxiliary support stands. The extending rails provide stable support for 12-foot trim pieces, transforming lengthy cuts from wrestling matches into straightforward operations.

Setup takes longer than simple folding stands—expect several minutes rather than seconds. The rail system requires proper alignment and secure locking, but once positioned, it handles long stock with confidence that separate support stands can't match.

The stand accommodates multiple saw brands through adjustable mounting, though the setup complexity means you'll want to keep the same saw mounted long-term. For trim carpenters or anyone regularly cutting long stock, the workflow improvement justifies the additional complexity.

Best for: Trim work, long stock cutting, shop use where setup time matters less than workpiece support, users willing to trade convenience for capability.

Kobalt KMS-S16 - Best Value Balance

The Kobalt delivers surprisingly solid performance at a price point that makes sense for occasional users or those testing whether a quality stand improves their workflow enough to justify premium options later.

The folding mechanism works smoothly without the precision engineering of more expensive alternatives. Setup takes slightly longer than top-tier options, but the process remains straightforward. The wheels handle smooth surfaces well and manage light gravel adequately, though they won't match pneumatic wheels on challenging terrain.

Build quality feels appropriate for the price—solid enough for regular use without the over-engineering that drives premium pricing. The universal mounting system accommodates most major saw brands with some adjustment required for optimal fit.

Best for: Budget-conscious users, occasional portability needs, testing whether a quality stand improves workflow, backup stand for multiple locations.

Festool Underframe UG - Premium Shop Solution

The Festool UG surprises with its portability despite the premium positioning. Large wheels and dolly-style transport make it genuinely mobile, and the lightweight construction means you can actually move it around job sites without a crew. The build quality reflects Festool's standards, but the design prioritizes mobility over absolute rigidity.

The mounting system integrates seamlessly with Festool's tool ecosystem, and setup is straightforward for users familiar with the brand's approach. However, the stand has enough flex that dedicated shop users might find it less satisfying than truly rigid alternatives.

The real cost consideration comes with the wings for long stock support—adding roughly $700 to an already premium-priced stand. This makes the complete system expensive for what you get, especially considering the mobility-focused compromises.

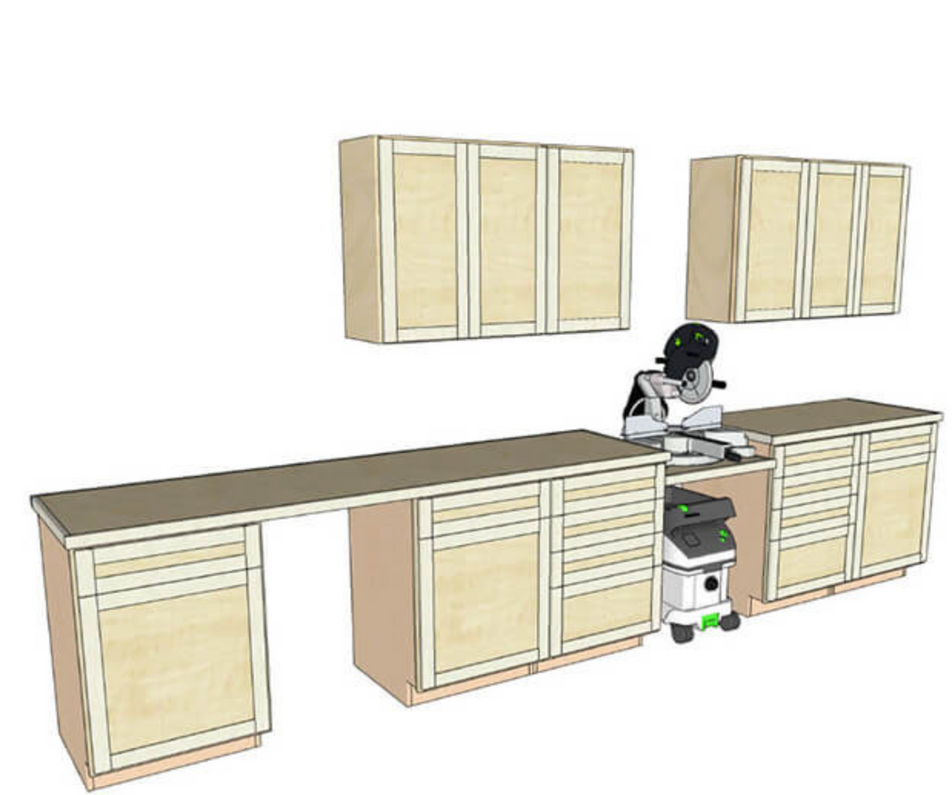

For stationary shop use, a well-built plywood miter saw station typically provides better stability and functionality at a fraction of the cost. We offer comprehensive plans for DIY miter saw stations that deliver superior shop performance without the premium pricing.

Best for: Festool ecosystem users who need genuine portability, job site work where mobility matters, users willing to pay premium prices for brand integration. Not ideal for: Dedicated shop setups where a DIY station would provide better stability and value.

Making the Right Choice

Start with your saw's weight and your actual portability needs. A 12" sliding compound saw that never leaves the shop doesn't need lightweight compromises that sacrifice stability. Conversely, job site work demands genuine mobility, even if it means accepting reduced support capacity.

Consider your typical workpiece length honestly. If you're cutting 12-foot crown molding regularly, extended support isn't optional, it's essential for both safety and accuracy. Don't underestimate this requirement.

Budget realistically for your usage level. The difference between a $200 compromise and a $400 purpose-built solution becomes apparent quickly with regular use. Factor in your time and frustration when making this decision. False economy rarely pays off with tools you use frequently.

The right miter saw stand disappears during use, providing stable, convenient support that lets you focus on the cut rather than fighting the setup. When you find yourself working around the stand's limitations rather than benefiting from its capabilities, it's time to upgrade.

Practical Advice & More Solutions for Every Workshop Challenge

At TSO Products, we engineer woodworking solutions that eliminate the daily frustrations experienced in shops and job sites across the country. From safety accessories to precision guides and project plans like this comprehensive miter saw station design, we focus on tools and resources that improve accuracy and efficiency—because when your equipment works seamlessly, you can focus on the craft instead of fighting your setup.

Recent Posts

-

Router Dust Collection: How to Tame One of the Dustiest Tools in Your Shop

Routers are among the most versatile tools in a woodworker’s shop—but they’re also …2nd Jul 2025 -

Top Miter Saw Stands: From Budget to Professional Grade

A miter saw without proper support turns precision cutting into guesswork. After years of dealing wi …2nd Jul 2025 -

Workshop Dust Collection: Smarter Setups for Safer Shops

Wood dust is more than just a nuisance—it’s a real hazard. While sweeping up chips might …12th May 2025