What Is a Guide Rail Square and How Do I Use It?

Track saws have become a mainstay in many woodworking shops, and for good reason. They excel at processing sheet goods, and with a little creativity plus the right accessories, they can help you accomplish many tasks traditionally reserved for a table saw or jointer. However, even a properly calibrated, high-quality track saw still relies on precise—and in most cases, square—placement of the guide rail. Guide rail squares were created to solve this problem for a majority of track-saw-cutting scenarios. Read on to learn more about guide rail squares, how to use them, and why they have become such a ubiquitous accessory for today's woodworkers.

What Is a Guide Rail Square?

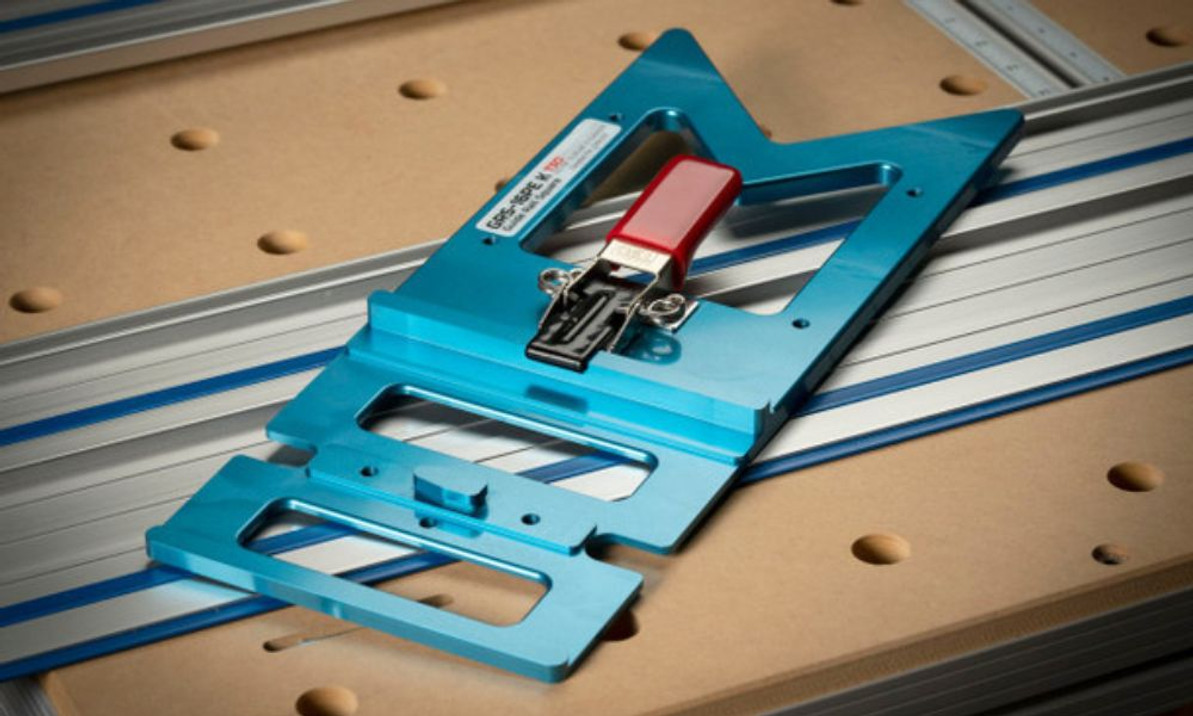

A guide rail square transforms your track saw guide rail into a very large square. It attaches to the guide rail by way of a clamping mechanism, staying rigidly attached and with a reference edge perfectly perpendicular to the guide rail.

Essentially, a guide rail square becomes an extension of your guide rail. The best guide rails are simple, one-piece designs that cannot drift out of the square. These extensions are quickly and easily attached to your guide rail. Guide rail squares also enable the use of other accessories, such as clamps, as well as provide good ergonomics and balance once attached.

With a guide rail square, you no longer have to rely on additional woodworking squares or triangles for 90° cuts. On the contrary, guide rail squares are self-aligning; you simply slide them onto your guide rail, clamp down the draw latch, and you’re ready to get to work.

How To Use Guide Rail Squares

To start using this essential accessory with your track saw, slide it onto your guide rail's T-track, then use the latch of the guide rail square to firmly clamp it down. Next, place the guide rail with the attached square onto the workpiece to be cut, firmly sliding the assembly forward so that the reference edge of the guide rail square fully contacts the front edge of the workpiece. You’re now ready to start making 90° cuts with your track saw. Guide rail squares sold by TSO Products come in two basic flavors: the GRS-16, the most compact square, which features a single reference edge at the top of the square, and the GRS-16 PE, which features two “parallel edges” at the top and bottom of the square, enabling it to reference off either the front or back edge of the workpiece. Both the GRS-16 and GRS-16 PE include a number of smart features, such as an integrated clamping notch which retains the ability to use clamps underneath the guide rail in combination with the guide rail square; tapped mounting points on the face of the square to attach handy accessories, like TSO’s Parallel Guide System; and a proprietary latch coating which provides additional grip while protecting the edge of your guide rail from marring.

Who Uses Guide Rail Squares?

If you’re already a track saw convert, chances are, you’ll find guide rail squares to be a big time-saver. From DIYers to woodworking professionals, anyone can benefit from adding a guide rail square to their sheet-processing arsenal.

Reasons To Use Guide Rail Squares

Increased Accuracy

A guide rail square ensures that the track saw is square to the front (or back) edge of your workpiece, helping to increase the accuracy of cuts. This is particularly useful when cutting sheet goods to size or when making precise cuts for joinery.

Saving Time

By allowing you to make precise square cuts quickly, a guide rail square can save time. In particular, you only have to mark your cutting line once when using a guide rail square, rather than scribing a line the entire length of the intended cutting position.

Versatility

A guide rail square can be used in combination with other accessories, such as a Parallel Guide System, to expand the capabilities of your track saw and further speed up your workflow.

Simplicity

A guide rail square is a simple tool; its only mission is to enable square cuts. The best guide rail squares are “born square” by design, feature limited to no adjustability (fewer points of failure), and are CNC milled to high tolerances from a material like aluminum.

Tips for Buying Guide Rail Squares

Now that we've discussed what guide rail squares are and how to use them, let's cover a few purchasing tips. This is no different than any other tool in your workshop, and you want to buy a top-quality item that fits into your budget.

Quality Matters

If budget allows, search for quality as you would with any woodworking tool. Typically, anodized aluminum makes for a great material thanks to its lightweight, durability, and high precision.

Compatibility with Guide Rail

As you shop for your guide rail square, carefully consider guide rail compatibility. While some guide rail manufacturers conform to a loose standard and feature similar profiles, some brands differ more than others, and these differences may necessitate dedicated guide rail square designs. For example, the Kreg Adaptive Cutting System (ACS) features a track saw that is designed to be operated left-handed, and consequently goes in the opposite direction along the guide rail compared to brands like Festool and Makita. For this reason, TSO developed a standalone “Kreg” version of their GRS-16, dubbed the GRS-16 PEK.

Read Customer Reviews

Pick a few different guide rail square options, then read the customer reviews. Does the product get high marks for results (accuracy)? Is it easy to install? How durable is it over time? Gathering all this information helps you find the right feature and budget fit.

Buy From TSO Products

As the category creator and patent holder, consider TSO for your precision woodworking square purchase. In addition to guide rail squares, TSO offers a full range of precision woodworking tools that include triangles, parallel guide systems, numerous workholding products, and other woodworking essentials.

Not sure which product is right for you? Contact us for support! We have years of experience and are always happy to help our customers find the perfect tool.

Recent Posts

-

Building Your Own DIY MFT/3-Style 20mm Workbench Table

The 20×96mm workbench standard popularized by Festool’s MFT/3 has become a go-to foundation in moder …27th Jan 2026 -

JessEm Stock Guides for DeWalt Table Saws: Precision & Consistency

JessEm Stock Guides give you consistent hold-down pressure, one-way feed control, and include a slig …19th Dec 2025 -

What Size Guide Rail Do I Need? Choosing the Right Length (and When to Use Extensions)

The scenario: you need to make a cut in that full size plywood panel sitting in the corner of your s …6th Nov 2025