Best Track Saw Systems: Expert Review & Advice

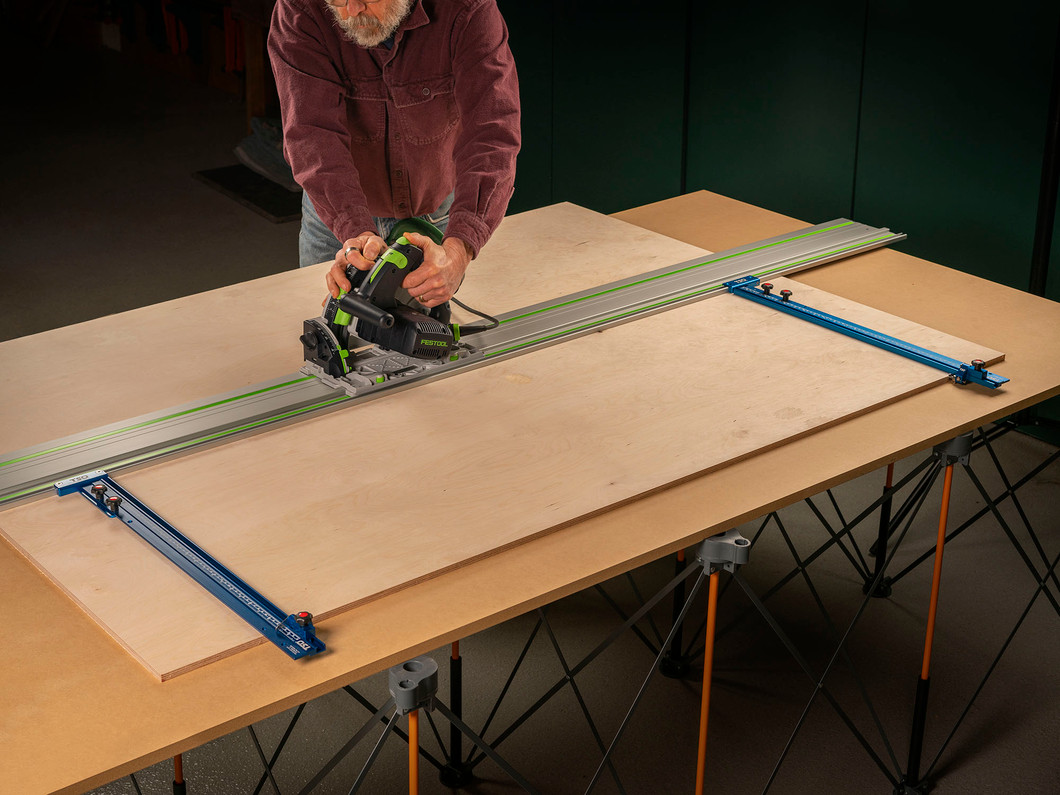

The track saw market has changed considerably over the past three years. Back then, your options were limited to premium European manufacturers like Festool and Mafell—exceptional tools but priced well beyond most hobbyist budgets. Today, brands like Makita, DeWalt, Milwaukee, and Kreg offer capable systems at much more accessible prices. More choices mean better access, but they also mean more decisions to make.

The right track saw system depends on how you work, what you build, and how your needs will evolve. Let's take a look at what makes these systems work and how to choose one that serves you well for years.

What Makes a Great Track Saw System

Before comparing specific brands, understand what separates a system you'll reach for from one that sits in the corner. If you're considering a track saw, you've likely already dealt with the frustration of breaking down sheet goods with a circular saw or wrestling full sheets across a table saw. You know what doesn't work. Here's what does.

Cut Accuracy and Track Stability

Your saw needs to stay on course through the entire cut. Any flex in the rail or slop in the base-to-rail interface shows up immediately in your work—wavy edges, out-of-square cuts, wasted material. When you're cutting $80 sheets of hardwood plywood, accuracy isn't academic.

The rail's anti-slip bottom should grip firmly without excessive clamps. Most modern track saws handle this well—even entry-level systems stay in place during cuts.

Ease of Setup and Alignment

You're likely working alone most of the time. The system needs to set up quickly without fighting you. Position the rail, check your marks, make the cut. If you're spending more time aligning than cutting, the system isn't doing its job.

This matters more as you make multiple cuts or work through a full sheet. A system that requires fussing for every cut turns a two-hour project into a four-hour project.

Dust Collection Performance

If you're cutting sheet goods regularly, dust collection isn't optional. Poor collection means you can't see your cut line clearly and you're breathing fine particles all day. Premium systems excel here—brands like Festool design their saws around optimized dust collection pathways and airflow, capturing significantly more dust at the source. They also offer purpose-built extractors with features like adjustable suction that work particularly well with track saws.

This becomes more important if you're working in a garage or basement shop where dust control matters beyond just cleanup. Budget systems will work with your shop vacuum, but expect more dust in the air and on your workpiece.

System Compatibility and Ecosystem

You're not just buying a saw, you're buying into a system. Can you add a second rail and join them accurately? Are stops and parallel guides available? Will you find compatible accessories in five years when you want to expand capabilities?

Premium systems extend beyond track saw use. Festool guide rails, for example, work with their routers for guided plunge cuts—eliminating the need for a router table for edge profiling or dado work. This cross-tool compatibility means your investment in rails and accessories serves multiple purposes in your shop. A well-developed ecosystem lets you accomplish more with the tools you already own rather than buying specialized equipment for every task.

Third-party manufacturers (like TSO Products) add further capability. Quality connectors, extensions, squares, and parallel guides can transform a basic system into a comprehensive cutting station. Some accessories work across brands—depending on rail geometry, you might use Makita rails with a Festool saw, or vice versa—though compatibility isn't universal.

If you're the type who builds workshop capabilities over time rather than buying everything at once, ecosystem matters. Systems with limited accessory options box you in later. Before committing to a platform, research what accessories exist now and whether the manufacturer has a history of supporting and expanding their system over time.

Ergonomics and Adjustability

Handle position affects how much control you have during cuts. Depth and bevel adjustments need to move smoothly but lock firmly—adjustments that slip mid-cut ruin work and create safety issues.

If possible, handle the saw before buying. Do a blade change, and interact with all of the buttons and touchpoints. You might find the process isn’t as straightforward as it could be. And if the feel isn’t right in your hand, what feels fine for five minutes in a store might cause fatigue after cutting a dozen sheets. Weight distribution matters too—a poorly balanced saw requires more effort to keep plunged properly.

Our Top Recommendations

After evaluating what matters in daily use, here's where different systems excel based on your specific situation and budget.

Quick Comparison

|

System |

Best For |

Key Strength |

Tradeoff |

|

Minimal budget/occasional use |

Low entry cost, cuts straight |

Basic controls, limited accessories, not built for frequent use |

|

|

Solid entry point |

Smooth operation, strong ecosystem, reliable accuracy |

Dust collection adequate but not exceptional |

|

|

Premium precision work |

Exceptional accuracy, excellent dust collection, comprehensive accessories |

Significant investment |

|

|

Cordless convenience |

Best cordless power, M18 platform integration |

Newer ecosystem still developing |

|

|

Cordless performance |

Strong power in battery platform, established rail system |

Higher initial cost for batteries |

|

|

Familiar brand reliability |

Easy to find, good service network |

Unique rail design limits third-party accessory compatibility (though TSO Products accommodates it) |

|

|

Entry-level/DIY |

Straightforward setup, approachable pricing |

Lots of plastic, Not built for heavy professional use, cuts in the opposite direction of most other track saws |

For Entry-Level Budget: WEN CT1065

WEN's track saw is a low barrier to entry in the market. It cuts straight and handles basic sheet goods breakdown, making it appealing for occasional users or those testing whether a track saw fits their workflow before investing more. The system works, but expect limitations—less refined controls, basic dust collection, and a minimal accessory ecosystem. If you're breaking down a few sheets per month and prioritize initial cost above all else, it's functional. For anyone planning regular use or wanting to expand capabilities over time, spending more upfront makes better sense.

For Budget-Conscious Corded Users: Makita SP6000J1

The Makita SP6000J1 with a 55" rail is an older design, but it remains a solid entry point for corded track saw work. It tracks smoothly, maintains accuracy over time, and benefits from Makita's established rail ecosystem with wide third-party accessory support. If you work primarily in the shop with consistent access to power and want to minimize initial investment, this system delivers reliable performance for serious hobbyists and professionals alike.

For Absolute Precision: Festool

If you're building fine furniture with expensive materials or running a professional cabinet shop where precision determines whether joints fit properly, Festool eliminates variables. You pay significantly more, but you get the best accessory compatibility, accuracy and dust collection that justify the cost when mistakes are expensive.

For Cordless Flexibility: Milwaukee M18 or Makita 40V

If you're already invested in M18 batteries, Milwaukee makes practical sense—solid power and performance without buying into another platform. Makita's 40V option provides similar cordless convenience with the benefit of their established rail ecosystem. Either works well for jobsite use or shops where cord management is problematic.

For Getting Started: DeWalt or Kreg

DeWalt offers a solid mid-range option with their established reputation for durability and serviceability. Their unique rail design allows cutting from either side, though it limits compatibility with most third-party accessories. Kreg offers a more DIY-friendly approach at a lower price point. Both get you into track saws without premium investment, though you'll notice refinement differences compared to higher-tier systems.

The right system depends on your actual use pattern. Breaking down a few sheets monthly? DeWalt or Kreg handles it fine. Cutting hardwood veneered plywood weekly? Makita or Festool makes more sense. Already running cordless in the field? Milwaukee or Makita battery options fit your workflow.

Choosing the Right System for Your Needs

Match the system to how you actually work, not aspirations or someone else's setup.

If you're new to track saws or work on occasional projects: Start with WEN CT1065, DeWalt, or Kreg. You'll get capable performance without overinvesting in features you won't use yet. These systems handle typical workshop tasks and give you room to learn what matters to you before upgrading.

If you're a serious hobbyist cutting sheet goods weekly: Makita's corded system or Milwaukee's M18 platform make sense. You need reliability and accuracy that hold up over time. The accessory ecosystem lets you expand capabilities as your skills and projects advance.

If you're a professional or precision is non-negotiable: Festool delivers the accuracy and dust collection that justify the cost when mistakes mean wasted materials and lost time. The system maintains performance under daily use and provides the comprehensive accessory support production work demands.

Corded vs. Cordless: Corded vs. Cordless: This decision comes down to where you work. If you're primarily in a shop with ready access to outlets, corded systems eliminate battery management and typically cost less upfront. For jobsite work or situations where running extension cords creates problems, cordless makes practical sense. Modern cordless track saws deliver comparable performance to corded models for typical sheet goods work—power isn't the limitation it once was. Factor in battery costs if you're not already invested in a platform, but don't assume cordless means compromised cutting capability.

The Accessory Ecosystem: Why It Matters

The saw and rail are your foundation, but accessories extend what the system can do.

Rail connectors let you join shorter rails for longer cuts. Two 55" rails connected with a quality connector give you more versatility than a single 110" rail—easier to store, simpler to handle, and more adaptable to different cutting situations. Poor connectors introduce alignment errors that defeat the purpose of a precision system.

TSO’s GRC-12 connectors join shorter guide rails with an auto-aligning keystone feature, allowing you to create longer, perfectly straight runs that expand cutting capacity without sacrificing accuracy or stability.

Rail extensions let you expand cutting capacity as your needs grow. Check compatibility with your system before buying—not all rails work with all track saws, though many can be used across brands.

The GRE-13 Guide Rail Extension is a rail extension built specifically for Festool FS rail systems. It combines a 13 5/8" section of genuine Festool guide rail with our GRC-12 self-aligning connectors, giving your 55" rail the extra reach needed for fully supported cuts across sheet goods.

For square cuts and repeatable dimensions, precision accessories transform your track saw into a full-featured cutting station. Guide rail squares like TSO’s GRS-16 series provide instant, tool-free 90° alignment for Festool, Makita, DeWalt, Kreg, Ridgid, and other major systems—eliminating setup errors and ensuring true crosscuts every time. Make repeatable, high precision cuts with ease using the TSO Parallel Guide System, transforming your track saw with cabinet-saw-level accuracy anywhere in your shop or on the jobsite.

Common Buying Mistakes to Avoid

Assuming all rails are cross-compatible. They're not. Different manufacturers use different profiles. Commit to one ecosystem or verify compatibility before buying. You can't mix DeWalt rails with Makita saws, for example.

Buying one long rail instead of modular sections. A single 110" rail seems simpler but it's heavy, awkward to store, difficult to deploy without damaging, and less versatile than two shorter rails joined with a quality connector. You'll appreciate the flexibility when you're working alone.

Ignoring dust collection performance. You won't know how much this matters until you're squinting through a cloud of dust trying to see your cut line. Check actual user reviews, not just specifications. Poor dust collection slows your work and affects your health.

Choosing based on brand loyalty alone. Your experience with a manufacturer's cordless drills doesn't predict their track saw performance. Evaluate the specific tool system, not just the logo. Exception: if you're deep in a battery ecosystem, staying with that platform for cordless makes practical sense.

Skipping accessory compatibility research. List the accessories you'll need—connectors, stops, parallel guides—and verify they exist and their cost before buying. Some systems look affordable until you discover limited accessory options or expensive add-ons.

Making Your Decision

The right track saw system depends on three factors: how often you'll use it, what precision your work demands, and how your needs will likely evolve.

Think in terms of complete systems, not just the saw. A $500 saw with $200 in quality accessories often outperforms a $700 saw with limited expansion options. Consider the rails, connectors, clamps and other accessories you'll need to work efficiently.

No universal "best" exists. Festool delivers exceptional precision at a premium price. Makita provides strong value in the mid-range. Milwaukee offers cordless convenience. DeWalt emphasizes local availability. Match the system to your actual workshop reality—your budget, your projects, your space.

At TSO Products, we engineer accessories that solve real problems woodworkers face with their track saw systems. We understand these tools because we use them daily in our own shop.

Take the time to choose well. A properly matched track saw system will serve you reliably for years, delivering accurate cuts and efficient workflow on everything from breaking down sheet goods to precision joinery.

Recent Posts

-

Building Your Own DIY MFT/3-Style 20mm Workbench Table

The 20×96mm workbench standard popularized by Festool’s MFT/3 has become a go-to foundation in moder …27th Jan 2026 -

JessEm Stock Guides for DeWalt Table Saws: Precision & Consistency

JessEm Stock Guides give you consistent hold-down pressure, one-way feed control, and include a slig …19th Dec 2025 -

What Size Guide Rail Do I Need? Choosing the Right Length (and When to Use Extensions)

The scenario: you need to make a cut in that full size plywood panel sitting in the corner of your s …6th Nov 2025